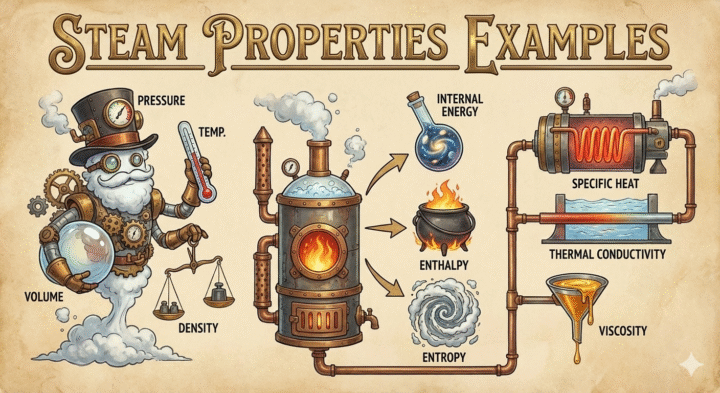

Steam is one of the most widely used working fluids in power plants, refineries, chemical industries, food processing units, and heating systems. To design, operate, and optimize steam-based systems efficiently, it is essential to understand the properties of steam. These properties are broadly classified into Physical, Thermodynamic, and Heat Transfer properties.

Physical Properties

1. Physical Properties of Steam

Physical properties describe the basic measurable characteristics of steam without involving energy interactions.

Pressure

Pressure is the force exerted by steam per unit area. It directly affects steam temperature, density, and energy content. Steam pressure is a key parameter in boilers, turbines, and pipelines.

Temperature

Steam temperature indicates the thermal state of steam. Depending on pressure, steam may exist as saturated steam or superheated steam. Temperature control is crucial for safe and efficient equipment operation.

Volume (Specific Volume)

Specific volume is the volume occupied by unit mass of steam. It increases significantly when water converts into steam, which explains the high expansion ratio during vaporization.

Density

Density is the mass per unit volume of steam. As pressure increases, steam density increases, and as temperature increases, density decreases. Density affects steam flow and heat transfer calculations.

2. Thermodynamic Properties of Steam

Thermodynamic properties relate to energy, work, and heat interactions of steam.

Internal Energy

Internal energy represents the total energy stored within steam due to molecular motion and intermolecular forces. It plays a major role in energy balance calculations.

Enthalpy

Enthalpy is the sum of internal energy and flow energy (pressure × volume). It is the most commonly used steam property in boilers, turbines, and heat exchangers for performance analysis.

Entropy

Entropy measures the degree of disorder or randomness in steam. It helps assess irreversibility and efficiency in thermodynamic processes such as expansion in turbines and compression in pumps.

3. Heat Transfer Properties of Steam

These properties define how steam transfers heat during heating, cooling, or flow.

Specific Heat

Specific heat is the amount of heat required to raise the temperature of unit mass of steam by one degree. It varies for water, saturated steam, and superheated steam.

Thermal Conductivity

Thermal conductivity indicates the ability of steam to conduct heat. It influences heat exchanger performance and insulation design.

Viscosity

Viscosity is the resistance offered by steam to flow. It affects pressure drop, flow behavior, and pumping power in steam pipelines.

Importance of Steam Properties in Industry

Understanding steam properties is essential for:

- Boiler design and fuel efficiency

- Turbine performance and power generation

- Heat exchanger sizing

- Energy audits and optimization

- Safe operation of steam systems

Steam tables and Mollier (h-s) charts are commonly used tools to determine these properties accurately under different operating conditions.

Steam properties form the foundation of thermal engineering and industrial energy systems. By analyzing physical, thermodynamic, and heat transfer properties, engineers can design safer, more efficient, and cost-effective steam-based processes. Whether in power plants or process industries, mastering steam properties is key to energy efficiency and operational excellence.