| Furnace oil CHARACTERISTICS | INSPECTIONS | REQUIREMENT | METHOD OF TEST |

|---|---|---|---|

| Spot test for cleanliness | 1 | No.2 Max (Faint or poor defined inner ring) | ASTM D 4740 |

| Acidity, inorganic | Nil | Nil | ASTM D 974 |

| Ash, Percent by mass | 0.040 | 0.1 Max | IS 1448 P-4 |

| Carbon residue, mass percent | 9.3 | 18 Max | ISO 10370 |

| Gross, calorific value | 10115 | To be reported | IS 1448 P-7 |

| Density at 15oC, kg/m | 969.8 | To be reported | IS 1448 P-16 |

| Flash point Pensky Martens (closed), in oC | 82.0 | 66 Min | IS 1448 P-21 |

| Kinematic viscosity in Centistokes at 50oC | 170.2 | 125-180 | IS 1448 P-25 |

| Sediment, percent by mass | 0.06 | 0.25 Max | IS 1448 P-30 |

| Sulphur, total, percent by mass | 3.170 | 4.0 Max | ISO 8754 |

| Water content, percent y volume | 0.4 | 1.0 Max | IS 1448 P-40 |

| Pour point*, (oC) | 9 | Winter: 15 Max Summer : 27 Max | IS 1448 P-10 |

| Ashphalteness, percent by mass | 6.0 | 10 Max | IS 1448 P-22 |

PRODUCT: Fuel Oil (MV2 GRADE)

*furnace oil : Winter shall be the period from Novenmber to February (both months inclusive.) and rest of the months of the year shall be called as summer.

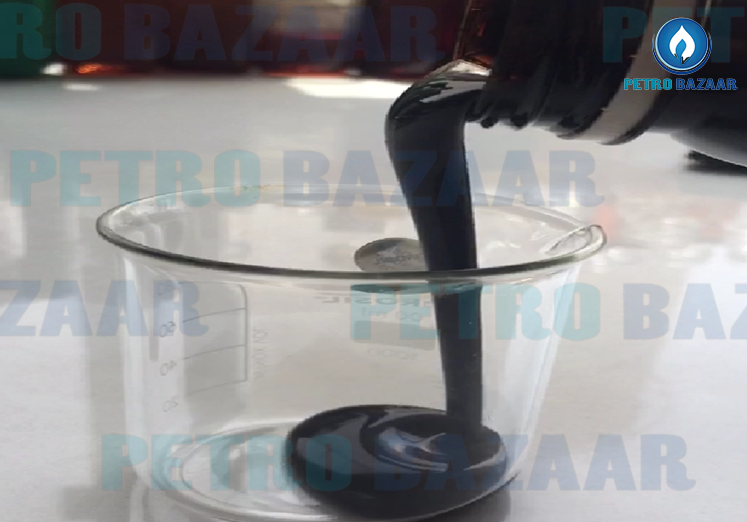

Furnace oil is a dark viscous residual fuel obtained by blending mainly heavy components from crude distiallation unit, short residue and clarified oil from fluidized catalytic cracker unit.

Viscosity

Furnace oil Viscosity is the most important characteristic in the furnace oil specification. It influences the degree of pre-heat requirement for handling, storage, and satisfactory atomization. If the oil is too viscous it may lead to difficult in pumping. Burner may be hard to ignite and operation may be erratic.

Poor atomization result in the carbon deposits on the burner surroundings. The upper viscosity limit for FO can be handled without pre-heating in the storage tank, accepting under server cold conditions. Pre-heating is key for proper atomization.

Water Content

Water may be present in free or emulsified from and can on combustion cause damage to the inside furnaces surgaces especially if it contains dissolved salts. It can also cause sputtering od the flame at the burner top. Water content of furnace oil when supplied is normally very low as the product at refinery site is handled hot and maximum limit of 1% is specified in the standard.

Furnance oil being a blend of residues contains some qunatity if sediments. There have adverse effect on the burners and cause blockage if filters etc. However, the typical values are normally much lower than the stipulated value of maximum 0.25%, by mass.

Ash

Ash is incombustible component of the furnace oil and is expressed as a percentage mass of the furnace oil sample. Ask consists of extraneous solids, residues of organimetallic compounds in solution and salts dissolved in water present in the fuel. These salts may be compounds of sodium, vanadium, calcium, magnesium, silicon, iron etc.

Ash has erosive effect on the burner tips, cause damage to the refractories at high temperatures and gives rise to high temperature corrisuve and fouling of equipments.

Sulphur

Sulphur determination includes burning of known quantity of oil, treating the sulphur oxidation products formed during combustion and weighing of sulphur in the form of sulphate. Heavy ends of crude distillation includes Furnace Oil, Low Sulphur Heavy Stock (LSHS), Residual Fuel Oil (RFO), Lube Oils, Bitumen, Petroleum Coke, Paraffin Wax, other waxes etc.